Plastic injection molding company in Illinois

Plastic injection molding is an advanced manufacturing technique that can be used to produce a variety of parts and products. However, not all plastic injection molding companies offer the same quality of services. For this reason, it is important to compare the top injection molding companies carefully to find the company that offers the best service.

How Does Plastic Injection Molding Work?

A plastic injection molding factory contains specialized equipment used to produce a variety of molded products based on customer specifications. During the plastic injection molding process, molten materials are injected into a mold cavity. While in the cavity, the molten material cools and hardens, taking on the desired shape. The quality of the products produced by a plastic molding company will depend on several factors, including the equipment used, the quality of the molds, the quality of the materials and the expertise of the people on staff. When choosing a plastic injection company, you need to consider all of these factors.

Working with Crestwood Industries

When it comes to plastic injection molding companies, you have a variety of options to choose from. At Crestwood Industries, we understand that you have options, and we strive to be the best at what we do. Below is an overview of some of the services we offer:

Plastic Injection Molding

Crestwood Industries offers comprehensive plastic injection molding services in-house. We can handle a range of customer needs, from creating a single prototype to high-volume production. We use state of the art molding machines to produce only the highest quality of materials for every client. At Crestwood, we are strongly committed to our clients, and we will not compromise on quality in any circumstance. Whatever your project may be, we will do everything in our power to deliver your parts on time and exceed your expectations.

We offer:

- Manufacture of small to medium component parts from engineering-grade resins, such as Polycarbonate, Nylon, Acrylic, Acetal and ABS

- Complex and multi-cavity tooling

- High precision, quality parts from low-tolerance and high-temperature resins

- Shot sizes specific to your application .05 oz to 32 oz.

- 22 presses, ranging in size from 22 to 390 tons

- Quality with tolerances ranging from 1 to 3 thousandths of an inch, which is appropriate for most projects, to as little as 2 microns

- Quantities ranging from 500 to 5 million units

We use advanced Systems and software to maximize the quality of our products. Our secondary operations include sonic welding, milling, tapping, drilling, testing and assembly.

Materials

The team at Crestwood Industries has decades of experience with the selection of materials for injection molding, and we put this experience to work for the benefit of our clients. Whether you need to work with basic polypropylene or an engineering grade polycarbonate, we will work closely with you and our resin suppliers to find the material that will be most effective for your project. We understand that our clients are on a budget, so we will always take pricing into consideration as well.

Whatever your specific needs may be, you can count on the team at Crestwood Industries to help you make the right selection. Some of the questions we may address as we move through the project development phase include:

- Does the product need to resist certain chemicals?

- Does the product need to be able to withstand extreme temperatures or exposure to UV light?

- Does the product need to be fire retardant?

- Does the product need a special coloring or any other additive?

Some of the engineering grade thermoplastic materials we work with include:

- Acrylic

- TPE

- Nylon

- ABS/Polycarbonate Blends

- Polycarbonate

- ABS

Some of the top commodity grade thermoplastic resins we work with include:

- High Impact Polystyrene (HIPS)

- Polypropylene

- Polystyrene

Mold Transfer and Maintenance Programs

At Crestwood Industries, we have extensive experience with mold transfer and maintenance. We have successfully managed a number of mold transfer programs, including both one mold and multiple part programs. In each case, we inspect the molds carefully and efficiently in order to get them into production as quickly and cost-effectively as possible. If you are interested in a mold maintenance program, we are happy to customize it based on your needs. Our maintenance programs typically include a daily inspection of your molds and all recommended preventative maintenance to prevent problems. We also handle repairs of all complexities.

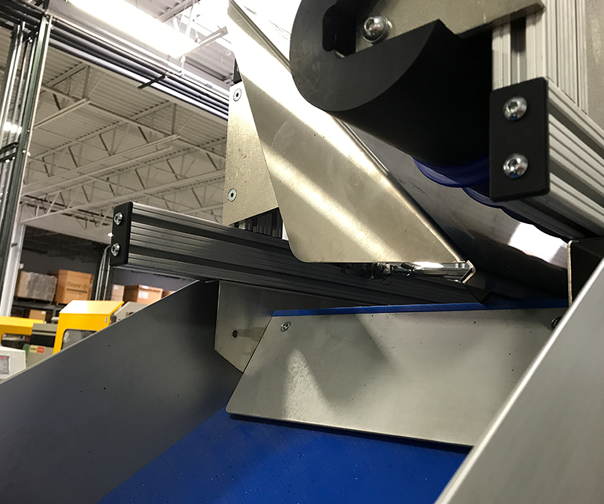

Precision Tooling Services

Our precision tooling services play an important role in our plastic injection molding factory. These services, along with our expertise, allow us to offer efficient production and exceptional product quality at all times.

Our team has many years of tooling experience, allowing us to improve time efficiency and save you money on all production runs. Crestwood Industries’ tooling services also offer additional opportunities for consolidation and quality control.

We offer a full range of tooling services for our clients, including:

- Engineering input on the viability and manufacturability of parts, as well as optimal tooling design

- Design and build new tools, including family tools and multi-cavity tools for molding machines ranging from 22 to 390 tons

- Tool testing and process development for consistency and accuracy

- Tool transfer for reshoring and consolidation

- Tool reconditioning, modification, maintenance and repair

Inventory Management

At Crestwood Industries, we want to become an extension of your existing operations so you can run your business as smoothly as possible. In order to provide a seamless flow of parts to your assembly line, our team works closely with purchasing and production planners at all times.

Some of the programs we currently have under management include:

- Kanban

- Lean

- Blanket Order

- Barcode

Crestwood Industries is one of the top plastic injection molding companies in the business. Contact us today to learn more about our services and how we can help your company grow.