Precision Injection Molding and Tooling Services

Precision injection molding, or precision tooling, is the craft of milling, shaping and fabricating components to match up to intricate specifications. The possibilities of precision specialty tooling are just about endless. It includes contoured grooves, chamfer edges, contoured slots and much more. Computer software allows three-dimensional products that are versatile and tough. Tools are made from durable materials and offer even more cutting abilities with carbide. If you are in the Chicago area and looking for precision injection molding in Illinois, stop by our shop for an informative tour.

The tooling process is a critical part of the manufacturing process. A precision molded plastics company offers this service for both speed and accuracy. There are many different types of tooling, such as extrusion machines, jigs, work holding tools and welding fixtures. It adds to the quality of the finished product. Many businesses feel that precision tooling services are too costly, but it is actually cost-effective due to today’s tool engineering techniques.

Why Use Precision Injection Molding?

There are many reasons to use precision tooling. Precision tool engineering is simple. It’s a one-stop solution that simplifies a complex task. It also lowers costs, as it can produce specialized parts quickly and reduce waste. It also gives you optimization in the market. You end up with an end product that is stronger and more efficient. By using one manufacturing technique, the whole engineering process is much simpler. It’s the cold forming that adds mechanical strength to the end product.

“While manufacturing space continues to be at the forefront of demand for precision measuring tools, medical and semiconductor industries are following suit and seeking precision measuring solutions of highest industry standards. In parallel with the ever-evolving demands, manufacturers of precision measuring tools are working on improving product reliability of their offerings. In addition, the manufacturers are also focusing on speeding up response time of the precise measuring tools and eliminating the risk of backlash problems, which, in turn, will help them to boost end user confidence and repeat sales.”

There has been a huge leap in the need for precision tooling in the global landscape. It’s just what folks today want. And the semiconductor industries and medical industries are following right along. Precision injection molding companies in Illinois like Crestwood are leading the way.

Crestwood Industries-The Top Precision Tool Company

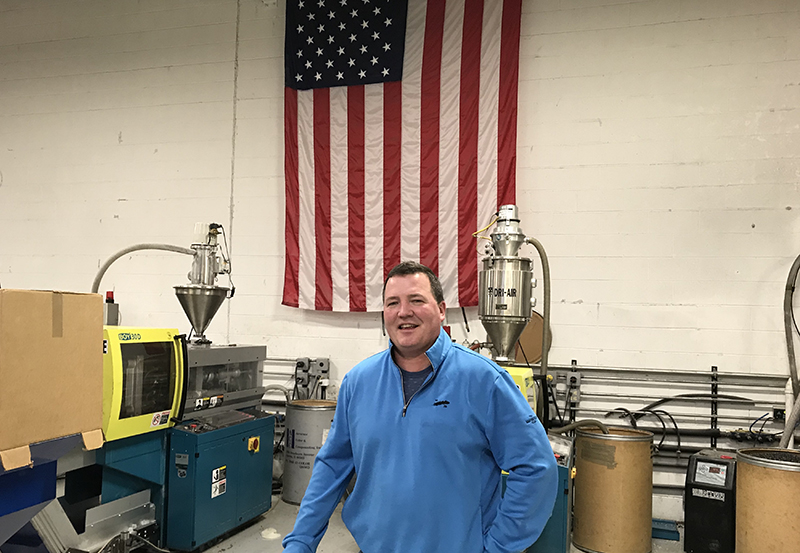

Crestwood Industries in Mundelein Illinois near Chicago offers precision injection molding and high-quality finished products. Experience, knowledge, skilled staff and intense quality control make Crestwood Industries a well-known name in the industry. They offer:

- Tool transfer for consolidation and re-shoring

- Tool maintenance, repair, modification and reconditioning

- Process development for accuracy and tool testing for quality

- The design of tools, such as family tools

- Engineering input on design, manufacturability and viability

Throughout the years, Crestwood Industries has developed tooling for novelty items, electronics, home building products, recreation and much more. Their hallmarks are precision, custom design, short production runs and long production runs.

If you’re seeking high-quality precision molded plastics products in Illinois or the vicinity, turn to Crestwood Industries for your project. Fill out their form, call or text them. They are always happy to speak to customers and answer any questions that you may have. Even get a quick quote or request a consultation. Contact Crestwood Industries – precision injection molding today for your unique production needs.